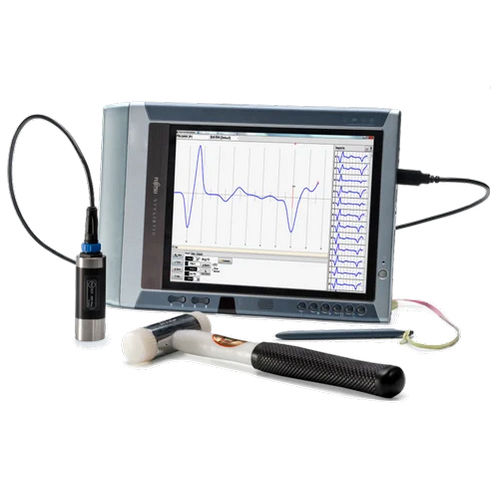

Pile Integrity Tester

Price 685000 INR/ Unit

Pile Integrity Tester Specification

- Material

- Metal

- Voltage

- 220-440 Volt (v)

- Usage

- Industrial

- Power Supply

- Electric

- Color

- Silver

- Product Type

- Pile Integrity Tester

Pile Integrity Tester Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Advance (CA)

- Supply Ability

- 30 Units Per Month

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

About Pile Integrity Tester

Advanced Pile Integrity Testing

Specifically engineered for industrial reliability, the Pile Integrity Tester helps construction professionals assess the physical condition and length of concrete piles without excavation. Its all-metal construction ensures durability and long-term performance, contributing to cost savings and efficient operation on-site.

Wide Voltage Compatibility

Designed with flexibility in mind, the tester operates smoothly within a voltage range of 220440 volts. This broad compatibility allows seamless integration into various electrical systems, making it a practical choice for diverse job sites across India.

Ease of Use and Reliable Results

With user-friendly controls and clear indicators, the Pile Integrity Tester simplifies the assessment process for both experienced engineers and new operators. Reliable test results help prevent costly structural failures, making it an indispensable investment for construction quality assurance.

FAQs of Pile Integrity Tester:

Q: How is the Pile Integrity Tester used in industrial applications?

A: The Pile Integrity Tester is deployed on construction sites to assess the structural integrity and length of concrete piles. It utilizes advanced non-destructive methods to detect cracks, voids, or other abnormalities, helping engineers make quick and accurate evaluations without damaging the pile.Q: What materials are used to manufacture the Pile Integrity Tester?

A: This device is primarily constructed from high-quality metal, ensuring strength and durability for industrial environments. The robust silver finish also offers protection against corrosion and physical wear during daily operations.Q: When should the Pile Integrity Tester be commissioned on a project?

A: The tester should be utilized during the pile inspection phase of any construction project, particularly before proceeding to subsequent structural work. Early detection of issues can prevent expensive setbacks and ensure compliance with safety standards.Q: Where can I purchase or source this Pile Integrity Tester in India?

A: You can obtain the Pile Integrity Tester from reputable exporters, service providers, suppliers, and traders across India. Many providers offer both product sales and after-sales support to ensure proper implementation and long-term satisfaction.Q: What is the process for operating the Pile Integrity Tester?

A: To operate the device, connect it to a 220-440 volt electric supply, follow the manufacturers instructions to calibrate, and then position the tester on top of the pile. The system will perform diagnostic analysis and provide data on pile soundness, typically within minutes.Q: What are the main benefits of using this Pile Integrity Tester?

A: Benefits include rapid, non-destructive assessment of pile integrity, enhanced safety, reliable data for decision-making, and lower costs by minimizing the need for physical excavation or pile replacement.Q: How does the power supply requirement affect usage on different sites?

A: The wide voltage compatibility (220440 volts) allows the tester to be used at various settings and construction locations without requiring special electrical arrangements, ensuring ease of deployment throughout India.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Civil Laboratory Testing Instruments Category

Automatic Titrator

Price 370000 INR / Unit

Minimum Order Quantity : 1 Unit

Power Supply : Electric

Usage : Industrial

Display Type : Digital, LCD

Equipment Type : Automatic Titrator

CHUM (CROSS HOLE ULTRASONIC MONITOR)

Price 2500000 INR / Kit

Minimum Order Quantity : 1 Meter

Power Supply : Rechargeable LithiumIon Battery, AC Adapter 100240V, 50/60 Hz

Usage : Structural quality assessment of deep foundation elements

Display Type : Large color capacitive touchscreen

Equipment Type : Cross Hole Ultrasonic Monitor

LABORATORY FURNACE

Price 50000 INR / Set

Minimum Order Quantity : 1 Degrees Fahrenheit

Power Supply : 230V AC, 50 Hz

Usage : Laboratory thermal processing

Display Type : Digital

Equipment Type : Laboratory Furnace

BANKELMAN BEAM APPARATUS

Price 20000 INR / Set

Minimum Order Quantity : 1 Meter

Power Supply : Not required (Mechanical device)

Usage : Civil Engineering, Road Construction

Display Type : Mechanical dial gauge

Equipment Type : Deflection Measurement Apparatus

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry