सभी उत्पाद देखने के लिए क्लिक करें Our Company

पलà¥à¤¸ वà¥à¤²à¥à¤¸à¤¿à¤à¥ ठलà¥à¤à¥à¤°à¤¾à¤¸à¥à¤¨à¤¿à¤ à¤à¥à¤¸à¥à¤à¤¿à¤à¤ सरà¥à¤µà¤¿à¤¸

पलà¥à¤¸ वà¥à¤²à¥à¤¸à¤¿à¤à¥ ठलà¥à¤à¥à¤°à¤¾à¤¸à¥à¤¨à¤¿à¤ à¤à¥à¤¸à¥à¤à¤¿à¤à¤ सरà¥à¤µà¤¿à¤¸ Specification

- Application

- Non-destructive testing of concrete structures

- Service Type

- Pulse Velocity Ultrasonic Testing Service

- Method Used

- Ultrasonic Pulse Velocity (UPV)

- Measurement Range

- up to 5000 m/s (material-dependent)

- Data Output

- Wave velocity, interpretation charts, structural analysis

- Standard Followed

- IS 516 (Part 5/Section 1)

- Testing Personnel Qualification

- Certified NDT technician

- Required Equipment

- UPV meter, transducers, coupling agent

- Test Material

- Concrete and other structural materials

- Typical Use Cases

- Detection of uniformity, cracks, and voids in concrete

- Test Duration

- Project dependent

About पलà¥à¤¸ वà¥à¤²à¥à¤¸à¤¿à¤à¥ ठलà¥à¤à¥à¤°à¤¾à¤¸à¥à¤¨à¤¿à¤ à¤à¥à¤¸à¥à¤à¤¿à¤à¤ सरà¥à¤µà¤¿à¤¸

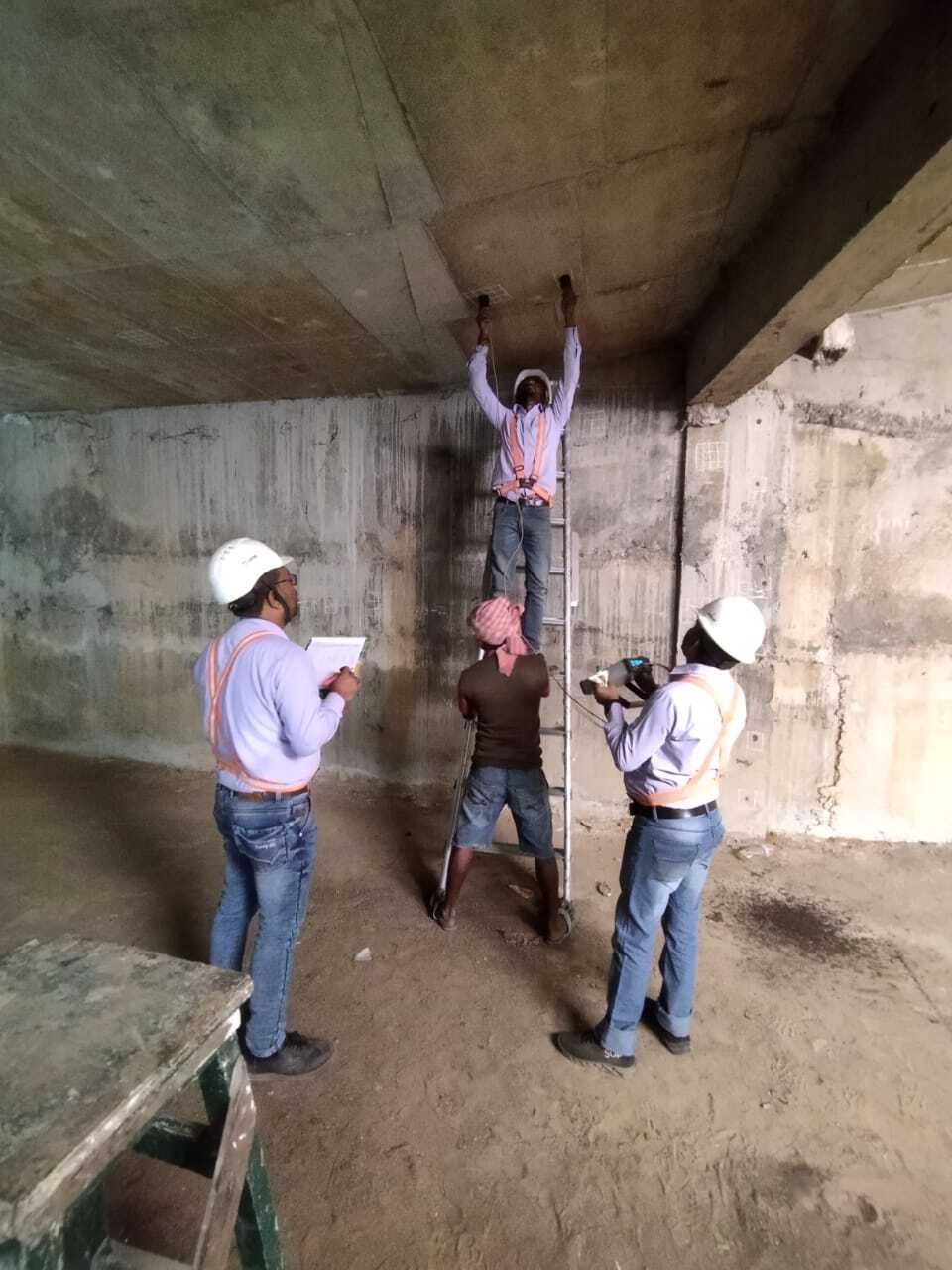

By measuring the speed at which ultrasonic pulses pass through concrete or other materials, the Pulse Velocity Ultrasonic Testing Service is a non-destructive testing technique that evaluates the consistency and quality of the material. The service entails sending and receiving pulse waves utilising ultrasonic transducers, signal generators, and receivers in order to assess the integrity of the material. The service is perfect for sectors including infrastructure, civil engineering, and construction because it uses cutting-edge engineering and acoustic technology. Clients gain from its ability to detect internal defects such as voids or cracks, guarantee material strength, maximise safety, and avoid expensive repairs, all of which enhance long-term structural dependability.

Accurate Concrete Assessment

Experience high-precision testing for concrete structures with our Pulse Velocity Ultrasonic Testing Service. Utilizing advanced UPV technology and certified personnel, we help you identify cracks, voids, and inconsistencies in a safe, non-destructive manner, ensuring your structures remain uncompromised and durable.

Comprehensive Reports and Analysis

After the ultrasonic testing is complete, we provide detailed data outputs, including wave velocity, interpretation charts, and expert structural analysis. These results support informed decisions for maintenance, repair, or quality control, all while meeting stringent industry standards.

FAQs of Pulse Velocity Ultrasonic Testing Service:

Q: How does the Pulse Velocity Ultrasonic Testing Service work for concrete materials?

A: This service uses Ultrasonic Pulse Velocity (UPV) equipment to transmit sound waves through concrete. By measuring the time it takes for the pulse to travel a known distance, we determine the wave velocity, which helps identify cracks, voids, and assess the uniformity of the structure without causing any damage.Q: What standards are followed during the ultrasonic testing process?

A: We strictly adhere to IS 516 (Part 5/Section 1) for Pulse Velocity Ultrasonic Testing, ensuring that all our procedures and reporting are in line with established national guidelines for non-destructive testing of concrete.Q: When should I consider using this service for my structure?

A: This service is recommended during quality assessments of newly constructed concrete, routine evaluations of existing structures, or when anomalies such as cracks or voids are suspected. It is suitable at any stage where concrete integrity is critical.Q: Where can this ultrasonic testing service be performed?

A: Our service is available throughout India and can be conducted on-site at various locations including construction projects, bridges, buildings, and infrastructure facilities where concrete or similar structural materials are used.Q: What is the process followed during UPV testing?

A: Certified NDT technicians position transducers on the surface of the material, apply a coupling agent, and initiate ultrasonic pulses. The velocity of the pulse is then measured and analyzed to detect internal flaws or evaluate uniformity as per the standard guidelines.Q: What are the advantages of using the Pulse Velocity Ultrasonic Testing Service?

A: The main benefits include non-destructive assessment, immediate results, the ability to detect internal cracks and voids, and obtaining quantitative data for structural analysis. This ensures timely maintenance decisions and long-term reliability of structures.Q: What equipment and qualifications are required for this testing?

A: We use UPV meters, specialized transducers, and coupling agents for precise measurement. All testing is conducted by certified NDT (Non-Destructive Testing) technicians to guarantee accurate and reliable results.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

अधिक Products in अल्ट्रासोनिक परीक्षण सेवा Category

पाइल डायनामिक्स टेस्टिंग इंस्ट्रूमेंट्स

न्यूनतम आदेश मात्रा : 2

माप की इकाई : मीटर

मूल्य या मूल्य सीमा : आईएनआर

मूल्य की इकाई : स्ट्रैंड/स्ट्रैंड्स

लो स्ट्रेन पाइल इंटीग्रिटी टेस्ट सर्विसेज

न्यूनतम आदेश मात्रा : 12

माप की इकाई : मीटर

मूल्य या मूल्य सीमा : आईएनआर

मूल्य की इकाई : सेट/सेट्स

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

जांच भेजें

जांच भेजें